References

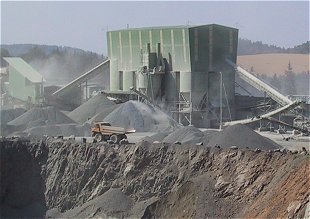

Crushing and Screening Plant

Crushing and Screening Plant

Year of Manufacture: 1993 / Scope of Delivery: Electrotechnical Equipment, Process Control Engineering

|

The newly built production plant consists basically of three parts. Primary crusher,

mineral processing section and loading station.

The mined material is crushed by the primary crusher and screened into two temporary silos. This part of the plant runs unattended. Video cameras are installed inside the plant. Monitoring is done from the central control station. The material is discharged from the temporary silos by conveying troughs or belt feeders and is fed to the crushers of the mineral processing section. The further crushed material is conveyed to screening machines and screened into the finished material silos. The process of crushing and screening is repeated depending on the required grain size and grading. The entire production process is automated to the greatest possible extent and is operated and controlled from the central control station. Operators can create production programs for the processing section, that allow the fully automatic operation. Within the capabilities of the plant, several production programs can run simultaneously, so that the optimum utilization is achieved. The loading of single grains and mineral mixes is done with an appropriate computer program. This software allows the time optimized and standardized loading. |

|

|

|